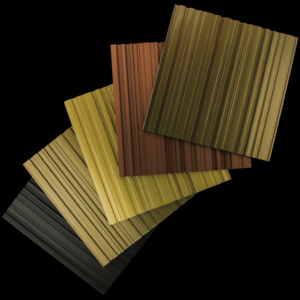

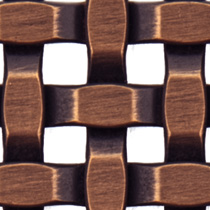

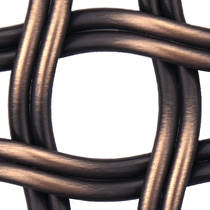

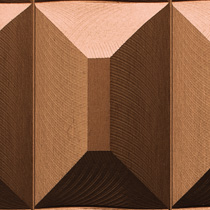

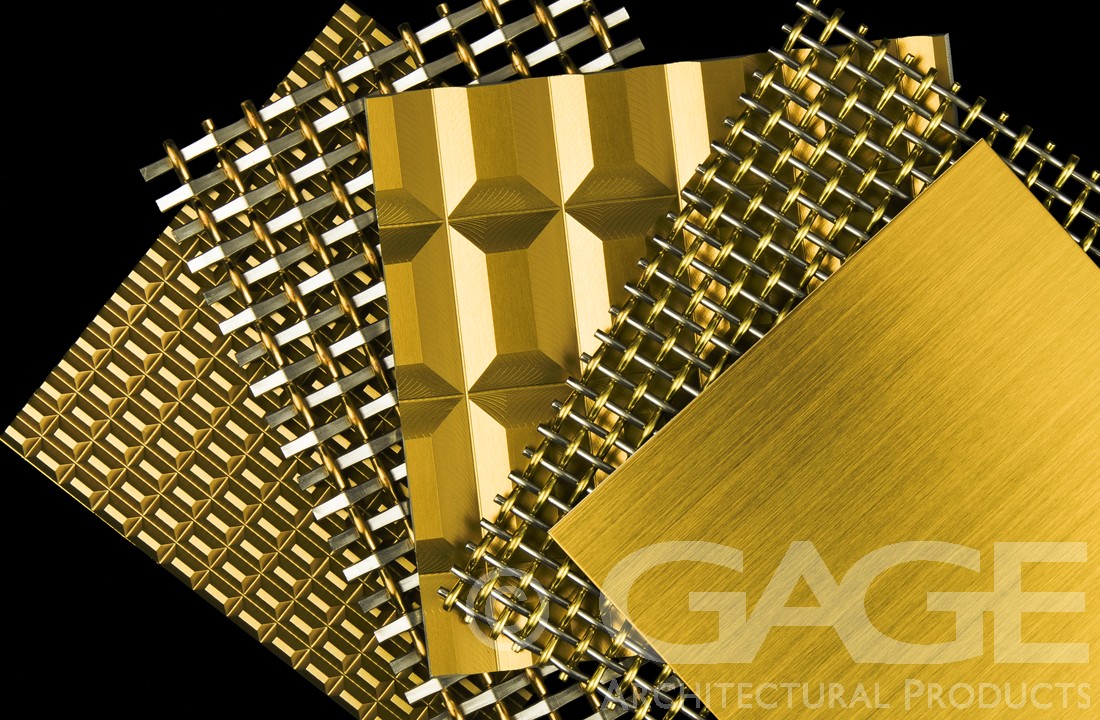

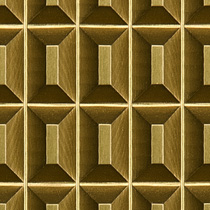

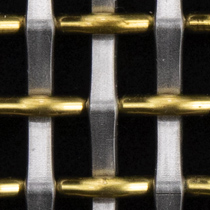

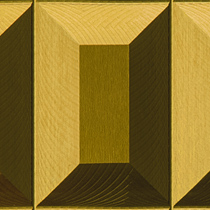

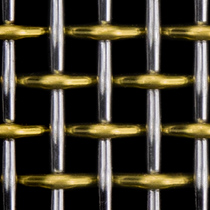

Decorative metal ceiling panel

Decorative metal ceiling panel

Plain sheet metals such as Stainless Steel, Brass, Bronze and Copper should only be cut with a metal shear. Such a cut will result in a minimal burr on the underside (the unfinished side) of the sheet, while “drawing” the cut on the finished side into very slight rounded edge: the “down-cut” edge. Thin gauge aluminum and metal laminates are generally cut by metal saws and hand tools. Deburring is done with routers and files.

A dull shear will cause significant burrs and pulling on the metal edge. It may also cause chipping and peeling of decorative finishes at the the sheet edge.

Sheet Sizes

Dimensions: Plain undecorated metal and metal laminates

Material Dimensions Inches: 48″ x 96″ or 48″ x 120″

Material Dimensions mm: 1220 x 2438 or 1220 x 3048

Specifiers should consider the most economical use of these standard sizes before designing a project. If the intended metal facing has formed edges, the overall standard blank size should always fall within the above dimensions.

Standard sheet size for PVD coated stainless steel is 48″ x 96″/1220 mm x 2438 mm.

Material Thickness

Plain metal sheets of architectural quality vary in thickness between .025″ (.60 mm) and .124″ (3 mm). Just as any other high traffic and high wear application, the specifier needs to consider minimum thickness to avoid denting.

Elevator surfaces such as doors and cab wall facings are usually specified in 18 gauge (0.050″ or 1.20 mm). If the plain metal sheet is glued to a solid substrate, such as steel, heavy plywood or particle board, then 20 gauge (0.040″ or 1.00 mm) Stainless Steel is sufficient. For an identical application in brass alloys (which are softer materials) we recommend to specify nothing less than 18 or 16 gauge (0.050″ or 0.060″) ( 1.20 mm or 1.50 mm). If the plain metal sheet is used for a hollow structure, such as a column cover, at least 16 Gauge Stainless Steel (0.124″ or 3.00 mm) Copper Alloys should be specified.

UNDER NO CIRCUMSTANCES CAN ANY DECORATED METAL SHEETS BE WELDED BECAUSE IT WILL DESTROY THE DECORATIVE FINISH IN THE WELDED AREA.

The specifier should avoid specifying highly decorated facings with metal which is too thin for the intended purpose. The resulting installation will look poor while the extra cost for decorated metal will be wasted.

Standard thickness for PVD coated stainless steel is 20 gauge/0.038″/0.95 mm.

Standard thickness for GM4724 Black Organic is 16 gauge/0.06″/1.52 mm.