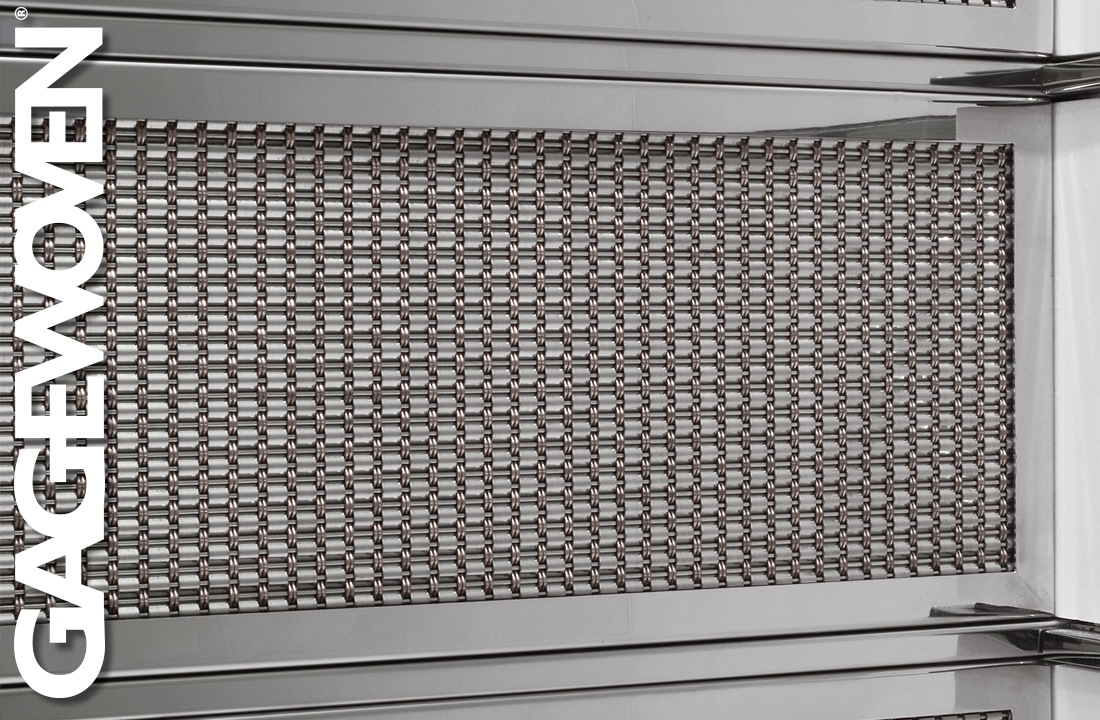

The Gage Corporation has been a leader in the development, design, and manufacture of specialty decorative metal architectural products since 1988. GageCeilings, GageMetal™, GageCarve™, and GageWoven™ are recognized internationally by the Architecture and Design community. Gage Architectural Products are specified extensively for the hospitality, retail, healthcare, corporate, and educational sectors.

Gage decorative metal products are suitable for almost unlimited vertical and horizontal applications including walls, elevator doors and interior wall panels, ceilings, columns, feature walls, furniture accents, desk inserts, and more. Most Gage products are manufactured in the United States of America.